For rapid reference, use the table below. In this simplification, it is assumed that all technologies can create the geometry from the component in question. When this isn't the case, 3D printing is normally the popular technique of manufacturing.

It is usually essential to think about the corresponding challenges beforehand over the machining process, including the chopping of significant-carbon steel should listen towards the don of the tool, and the sharp edge cracking of your pieces should be paid notice on the minimal-carbon steel.

Combining the features of lathe and milling equipment, the tool can go forward the three linear axes of X, Y and Z, and the workpiece can rotate within the A axis just like a turning machine, which can be appropriate for machining components with a lot more complex surfaces and extremely-significant precision needs.

In the actual creation approach, a variety of procedures tend to be needed to cooperate Along with the creation of a product. CNC machining is usually used in the write-up-processing means of forging and casting parts.

CNC machining is extensively Utilized in the health care industry to supply numerous health care gadgets and machines, such as surgical devices, implants, and prosthetics. The versatility of CNC machining components allows manufacturers to work with diverse resources like stainless steel, titanium, and plastics.

The detailed information gives you the fundamentals, style concerns, products, floor end, Value, and more details on CNC machining to assist you to develop quality machined areas with aesthetic overall look. Obtain Even with CNC machining currently being a lengthy-standing presence inside our lives, it’s astonishing that lots of people stay unfamiliar using this manufacturing approach.

Pick the most important thread probable, as they are simpler to device. Threads for a longer time than 3 contract manufacturing occasions the nominal diameter are avoidable.

As the key sponsor on the Match, the competition will have the identify of the auto manufacturer Company.

Surface area finishes can also change the Attributes of CNC machined elements and We'll study them below.

It is crucial to Understand that get started-up fees are fastened. There is an opportunity to appreciably reduce the device value for every component by Profiting from ’economies of scale’, as we saw previously mentioned.

Rz is measured by right measuring the difference in peak concerning the highest and least expensive points in the sample size, and it is utilized to measure the roughness of significant parts.

Manufacturers are deemed a significant part of the financial state. Manufacturing is usually traced back again to the ancient world. Nevertheless, For lots of hundreds of years, the typical manufacturer was an individual expert artisan with assistants.

Closed die forging necessitates the usage of molds, which might deliver parts with superior precision and complex styles.

Velocity: CNC machining is often more rapidly for developing metal areas, as it could possibly eliminate content additional speedily than 3D printing can Construct them. For compact-scale manufacturing and prototyping of plastic sections, 3D printing can be more quickly resulting from its layer-by-layer approach.

Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Burke Ramsey Then & Now!

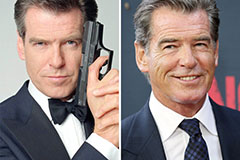

Burke Ramsey Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!